Exploring What Jewels in a Watch Mean

Key Highlights

- Watch jewels are essential components in a watch movement that reduce friction and enhance the durability and accuracy of the watch.

- They are not actual precious stones like diamonds or emeralds, but synthetic rubies or sapphires that serve a functional purpose.

- The use of jewels in watchmaking dates back to the 18th century when watchmakers discovered that these stones were harder and less abrasive than metal parts.

- Different types of jewels, such as hole jewels, cap jewels, pallet jewels, and roller jewels, have specific roles in reducing friction and supporting the movement.

- The number of jewels in a watch does not determine its value, but it does indicate the complexity of the movement and potentially its timekeeping performance.

Introduction

When we think of jewels in the context of watches, our minds often conjure up images of sparkling diamonds or colorful gemstones adorning the dial or case of a timepiece. However, in the world of watchmaking, the term “jewels” has a different meaning altogether. Jewels in a watch are not decorative elements but rather essential components that play a crucial role in the mechanical movement of the watch’s caliber.

In this blog, we will dive into the world of watch jewels and explore their significance in watch mechanics. We will discuss the function of jewels in reducing friction and enhancing the durability of watches, the different types of jewels used, and how they have evolved throughout history. Additionally, we will shed light on the impact of jewel count on a watch’s value and performance. By the end of this blog, you will have a comprehensive understanding of the meaning and importance of jewels in a watch.

The Role of Jewels in Watch Mechanics timekeeping

At the heart of every mechanical watch is its movement, which consists of numerous intricate and precisely crafted moving parts. These parts work in harmony to measure and display the passage of time. However, the constant movement and interaction between these components can lead to friction and wear over time, affecting the accuracy and longevity of the watch.

This is where watch jewels come into play. Jewels, typically made from synthetic rubies or sapphires, are strategically placed within the watch movement to act as bearings for the moving parts. These gemstone bearings provide a smooth surface with minimal friction, allowing the gears and wheels to rotate freely and reducing the wear and tear on the metal parts. In essence, the gems act as a lubricant, ensuring the efficient and precise functioning of the watch.

Enhancing the Durability of Watches

The use of jewels in watch movements significantly enhances the durability of watches. As mentioned earlier, the jewels act as bearings, reducing the friction between the moving parts. Friction is the enemy of accurate timekeeping, as it can cause the components to wear down and affect the smooth operation of the watch. Additionally, the use of jewels can prevent corrosion and premature wear, ultimately extending the lifespan of the watch.

By incorporating jewels into the watch’s design, watchmakers can minimize the friction between the moving parts, ensuring a longer lifespan for the watch. The jewels provide a hard and smooth surface for the metal components to rotate on, reducing the wear and tear on these crucial parts and enhancing the durability of the watch for a long time. This, in turn, leads to improved timekeeping accuracy and a more robust and reliable timepiece overall.

In addition to reducing friction, the jewel bearings also help to distribute the forces and stresses within the watch movement more evenly. This further contributes to the durability of the watch, as the components are less likely to be subjected to excessive strain or wear in specific areas. Ultimately, the use of jewels in watch mechanics is a testament to the craftsmanship and precision required to create a high-quality timepiece.

Reducing Friction and Wear in Movement

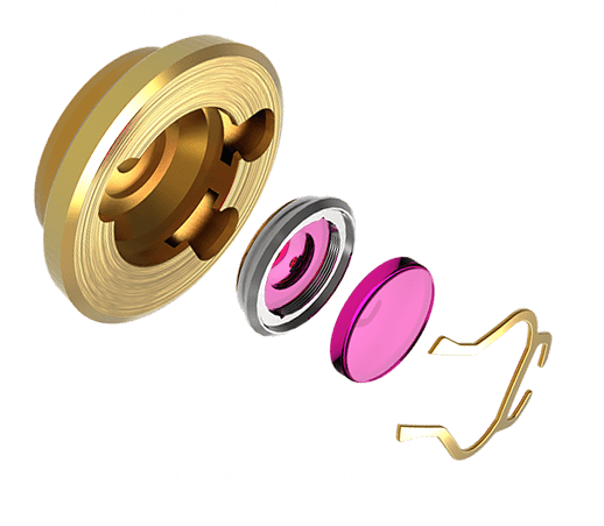

The reduction of friction and wear in a watch movement is crucial for its optimal performance and longevity. Watch jewels play a vital role in achieving this by providing smooth surfaces for the moving parts to rotate on. Let’s explore the specific components and their functions in more detail:

- Pallet Jewels: Pallet jewels are rectangular-shaped jewels located at the ends of both arms of a pallet fork. The pallet fork is a critical component in the watch movement’s lever escapement system, regulating the flow of energy between the balance wheel and the escape wheel. The pallet jewels provide a low-friction interface between the pallet fork and the escape wheel, ensuring smooth movement and accurate timekeeping.

- Balance Staff: The balance staff is a central component of the watch movement that supports the balance wheel, which oscillates back and forth to regulate the timekeeping. Cap jewels, also known as capstones, are used in conjunction with springs on either end of the balance staff to minimize its motion and provide shock resistance.

- Pivot Jewels: Pivot jewels are used in various parts of the watch movement, including the balance wheel, escape wheel, and other rotating components. These jewels have holes drilled in their centers, allowing them to be mounted on the wheel’s axle or pivot. Pivot jewels reduce friction and wear at the pivot points, ensuring smooth rotation and accurate timekeeping.

The strategic placement of these jewels within the watch movement significantly reduces friction and wear, thereby improving the watch’s overall performance and durability.

Types of Jewels Used in precision Watches

While the term “jewels” may evoke images of precious gemstones, the jewels used in watch movements are not the same as those found in jewelry. In watchmaking, jewels are typically synthetic rubies or sapphires. Let’s explore the different types of jewels commonly used in watches:

- Rubies: Rubies, made from synthetic corundum, are widely used in watch movements due to their hardness and durability. Synthetic rubies are created through a process called flame fusion, which allows for cost-effective production without compromising quality. Rubies are chosen for their exceptional hardness on the Mohs scale, making them ideal for reducing friction in high-precision mechanical movements.

- Sapphires: Like rubies, sapphires are also made from synthetic corundum and offer similar properties. They are often used in watch movements for their hardness and resistance to scratching. Synthetic sapphires provide a smooth surface for the moving parts, ensuring minimal friction and wear.

- Diamonds: While diamonds are known for their beauty and rarity, they are rarely used as watch jewels due to their cost and the limited functional benefits they offer. Synthetic diamonds, however, may be used in certain high-end watches for their exceptional hardness and durability.

It’s important to note that the use of synthetic jewels in watch movements does not diminish their functionality or performance. Synthetic rubies and sapphires provide the necessary hardness and smoothness required to reduce friction and ensure the reliable operation of the watch.

Rubies, Sapphires, and Diamonds

Rubies, sapphires, and diamonds are all classified as precious stones and are renowned for their beauty and rarity. In the world of watchmaking, these gemstones serve a different purpose as synthetic versions known as watch jewels. Let’s explore these precious stones, specifically rubies, sapphires, and diamonds, and their significance in the context of watch movements in modern watches:

- Rubies: Rubies, or synthetic corundum, are widely used in watch movements due to their exceptional hardness. They are rated 9 on the Mohs hardness scale, second only to diamonds. This hardness makes them ideal for bearing surfaces in watch movements, reducing friction and wear. Synthetic rubies are cost-effective to produce and offer consistent quality, making them a popular choice among watchmakers.

- Sapphires: Sapphires, also made from synthetic corundum, share similar properties with rubies. They are highly durable and scratch-resistant, making them suitable for use in watch movements. Synthetic sapphires provide a smooth and low-friction surface for the moving parts, ensuring the reliable operation of the watch.

- Diamonds: While diamonds are the hardest known natural material, they are rarely used as watch jewels due to their cost and limited functional benefits. However, certain high-end watches may incorporate synthetic diamonds in their movements for their exceptional hardness and durability.

In summary, the use of rubies, sapphires, and diamonds in watch movements highlights the importance of durability, hardness, and low-friction properties in maintaining the accuracy and longevity of a watch.

Synthetic vs. Natural Jewels

The use of synthetic jewels in watch movements has become the industry standard due to their affordability, consistent quality, and functional benefits. Let’s explore the differences between synthetic and natural jewels:

- Synthetic Jewels: Synthetic jewels, such as synthetic rubies and sapphires, are man-made versions of the natural gemstones. They are produced using various techniques, including the flame fusion method pioneered by Auguste Verneuil in 1902. Synthetic jewels offer the same hardness and low-friction properties as their natural counterparts but at a lower cost. They provide watchmakers with a reliable and cost-effective solution for reducing friction and ensuring the smooth operation of watch movements.

- Natural Jewels: Natural jewels, such as natural rubies, are rare and precious gemstones. However, their use in watch movements has become increasingly rare due to their limited availability and higher cost. Natural rubies are harder to source and often have imperfections that can affect their suitability for use in high-precision mechanical movements. Synthetic jewels provide a consistent and reliable alternative without compromising on performance.

While natural jewels may hold a certain allure and prestige, synthetic jewels offer the same functional benefits at a more accessible price point, making them the preferred choice for watchmakers.

Historical Evolution of Jewels in Timepieces

The use of jewels in watch movements has a rich history that dates back to the early days of watchmaking. In the early 18th century, watchmakers faced the challenge of reducing friction and wear in their timepieces. The breakthrough came when Swiss watchmakers Jacob Debaufre, Peter Debaufre, and Nicolas Fatio developed jewel bearings, including garnet, for their watch movements in 1704.

The Debaufre brothers and Fatio received an English patent for their innovative use of jewels as bearings in watch movements. This marked the beginning of a new era in watchmaking, as other watchmakers soon followed suit and embraced the use of jewels to enhance the performance and durability of their timepieces.

From Practical Use to Status Symbol

Over time, the use of jewels in watch movements evolved from a practical solution to a symbol of luxury and craftsmanship. As watchmaking advanced, the incorporation of jewels became a mark of quality and precision.

Luxury watch brands began using higher jewel counts in their movements as a way to showcase their technical prowess and attention to detail. The number of jewels in a watch movement became a status symbol, with higher counts often associated with higher-end timepieces.

However, it’s important to note that the number of jewels alone does not determine a watch’s overall quality. Other factors, such as the craftsmanship, complications, and materials used, also play a significant role in determining a watch’s value and desirability.

Milestones in Jewel Incorporation Techniques

The incorporation of jewels in watch movements has seen significant milestones throughout history. Let’s explore some notable moments in the evolution of jewel incorporation techniques:

- 1704: Nicolas Fatio de Duillier, Jacob Debaufre, and Peter Debaufre receive an English patent for their development of jewel bearings in watch movements.

- 18th century: Watchmakers begin using jewel bearings in their movements to reduce friction and enhance timekeeping accuracy.

- 1902: Auguste Verneuil develops the flame fusion process for creating synthetic gemstones, including rubies and sapphires. This revolutionizes the production of watch jewels, making them more accessible and cost-effective.

- 1974: The ISO 1112 standard is established, prohibiting watch companies from including unnecessary (non-functional) jewels in their advertising. This ensures greater transparency and accuracy in the representation of jewel counts in watches.

The continuous innovation and refinement of jewel incorporation techniques have contributed to the development of more precise and reliable watch movements over time.

How Jewels Influence a Watch’s Value and Performance

The number of jewels in a watch movement can have an impact on both its value and performance. While the number of jewels alone does not determine the quality of a watch, it is indicative of the complexity and potential timekeeping accuracy of the movement.

In general, a higher jewel count in a watch movement signifies a greater level of mechanical complexity. More jewels often imply additional complications beyond simple timekeeping, such as chronographs or dual time zones. These complications require more parts and mechanisms, which in turn necessitate a higher number of jewels to reduce friction and ensure smooth operation with minimal positional errors.

However, it’s essential to note that a higher jewel count does not guarantee a better watch. Other factors, such as the craftsmanship, materials, and design, also contribute to a watch’s overall value and performance.

Impact on Accuracy and Longevity

The use of jewels in a watch movement has a direct impact on its accuracy and longevity. The reduction of friction achieved through jewel bearings allows the components to move smoothly, resulting in improved timekeeping accuracy.

Jewels provide a low-friction interface for the moving parts, minimizing wear and tear on the metal components. This reduction in friction ensures that the watch operates reliably over an extended period. The longevity of the watch is enhanced as the jewels act as a protective barrier, preserving the integrity of the movement by preventing excessive strain and wear.

Higher jewel counts in watch movements often indicate a more complex and sophisticated timepiece. The additional jewels help to distribute the forces and stresses within the movement more evenly, further enhancing the watch’s accuracy and longevity.

Perception of Luxury and Craftsmanship

The inclusion of jewels in a watch movement has a significant impact on the perception of luxury and craftsmanship associated with a timepiece. Luxury watch brands often highlight the jewel count as a testament to their technical expertise and attention to detail.

A higher jewel count is often associated with higher-end watches, as it signifies a greater level of mechanical complexity and precision. The use of jewels showcases the watchmaker’s dedication to creating a reliable and accurate timepiece.

Additionally, the presence of jewels in a watch movement adds a touch of elegance and sophistication. It elevates the overall aesthetic of the watch, reinforcing its status as a luxury accessory.

Ultimately, the perception of luxury and craftsmanship associated with a watch goes beyond the number of jewels. Factors such as the brand reputation, materials used, and overall design also play a significant role in shaping the perception of a timepiece.

Deciphering Jewel Count in Watch Specifications

When exploring watch specifications, you may come across the term “jewel count,” which refers to the number of jewels used in the watch movement. The jewel count can vary significantly depending on the type of watch and its complexity. Here’s what you need to know about deciphering jewel count in watch specifications:

- Mechanical Watches: Mechanical watches typically have a higher jewel count compared to quartz watches. The number of jewels in a mechanical watch can range from 17 to over 40, depending on the complexity of the movement.

- Quartz Watches: Quartz watches, which rely on electronic mechanisms rather than mechanical components, may have few or no jewels. The precise timekeeping of quartz movements is achieved through the use of oscillating quartz crystals, eliminating the need for jewel bearings.

It’s important to note that the jewel count alone does not determine the quality or performance of a watch. Other factors, such as the brand reputation, movement design, and craftsmanship, should also be considered when evaluating a timepiece.

What Does the Number of Jewels Indicate?

The number of jewels in a watch movement indicates its complexity and potential timekeeping accuracy. While the jewel count alone does not determine the quality of a watch, it provides valuable insights into the inner workings of the timepiece. Here’s what the number of jewels typically signifies:

- Balance Wheel: The balance wheel is a crucial component in a watch movement that oscillates back and forth to regulate the timekeeping. The number of jewels associated with the balance wheel indicates the level of precision and accuracy achieved in its design and construction.

- Escape Wheel: The escape wheel is responsible for transferring energy from the mainspring to the balance wheel. The number of jewels associated with the escape wheel can indicate the complexity of the escapement mechanism and the level of precision achieved in its operation.

In general, a higher jewel count in these key components suggests a more precise and intricately engineered movement. However, it’s important to consider other factors, such as the craftsmanship and materials used, when evaluating a watch’s overall quality and performance.

Misconceptions About Jewel Count and Quality

There are common misconceptions surrounding the relationship between jewel count and the quality or value of a watch. It’s important to debunk these misconceptions and gain a more accurate understanding of how jewel count relates to a watch’s overall performance.

One misconception is that a watch with a higher jewel count is always of better quality or more valuable. While a higher jewel count can indicate a more complex and technically advanced movement, it does not guarantee superior quality or performance. In fact, some companies may add extra jewels to their watches as a marketing tactic, leading to the misconception that more jewels automatically mean higher quality. Other factors, such as the craftsmanship, materials, and design, also contribute to a watch’s overall quality.

Another misconception is that more jewels always result in better timekeeping accuracy. While jewels reduce friction and contribute to accurate timekeeping, the number of jewels alone is not the sole determinant of a watch’s accuracy. Factors like the movement design, regulation, and adjustment also play a significant role in achieving precise timekeeping.

It’s essential to consider the overall craftsmanship, brand reputation, and materials used when evaluating a watch’s quality, rather than solely relying on the jewel count.

Maintenance and Care for Jeweled Watches

To ensure the optimal performance and longevity of jeweled watches, proper maintenance and care are essential. Here are some key considerations for maintaining and caring for your jeweled watch:

- Regular Servicing: Regular servicing by a professional watchmaker is crucial to keep the watch in optimal condition. This includes cleaning, lubricating, and adjusting the movement. Regular servicing intervals vary depending on the brand and model but are typically recommended every 3-5 years.

- DIY Tips: While professional servicing is recommended, there are some DIY tips to keep your jeweled watch in good condition. Avoid exposing the watch to extreme temperatures or magnetic fields, as this can affect its accuracy. Clean the watch regularly using a soft cloth to remove dirt and oils. Avoid touching the jewels directly to prevent damage.

By following these maintenance and care tips, you can ensure the longevity and reliable performance of your jeweled watch.

Regular Servicing for Optimal Performance

Regular servicing by a professional watchmaker is essential for preserving the optimal performance and longevity of a jeweled watch. During servicing, the watch movement is carefully inspected, cleaned, lubricated, and adjusted as needed. Here’s why regular servicing is crucial:

- Cleaning: Over time, dirt, dust, and oils can accumulate within the watch movement, affecting its performance. Regular cleaning removes these contaminants, ensuring smooth operation and accurate timekeeping.

- Lubrication: Proper lubrication of the moving parts is critical to reduce friction and wear. During servicing, the old lubricants are removed, and new, high-quality lubricants are applied to ensure optimal performance and longevity.

- Adjustment: Regular servicing allows for the adjustment of various components within the watch movement, such as the escapement, balance wheel, and gears. These adjustments ensure precise timekeeping and optimal performance.

By adhering to the recommended servicing intervals and entrusting your watch to a qualified professional, you can maintain the optimal performance and longevity of your jeweled watch.

DIY Tips for Watch Enthusiasts

While professional servicing is recommended for jeweled watches, there are some DIY tips that watch enthusiasts can follow to care for their timepieces. Here are some key tips to keep in mind:

- Avoid Extreme Conditions: Protect your watch from extreme temperatures, as they can affect the accuracy and performance of the movement. Avoid exposing your watch to direct sunlight for extended periods or extreme cold temperatures.

- Avoid Magnetic Fields: Keep your watch away from strong magnetic fields, as they can disrupt the functioning of the movement. Magnetic fields can affect the accuracy and timing of a watch, so it’s best to store your watch away from magnets or electronic devices.

- Clean with a Soft Cloth: Regularly clean your watch with a soft, lint-free cloth to remove dirt, oils, and fingerprints. Avoid using harsh chemicals or abrasive materials that can damage the watch’s finish or scratch the crystal.

By following these DIY tips, you can ensure that your jeweled watch stays in good condition and continues to perform at its best.

Conclusion

In conclusion, the presence of jewels in watch mechanisms serves a vital purpose in enhancing durability and reducing friction. Understanding the types of jewels used, from rubies to diamonds, sheds light on their historical evolution from functional to prestigious elements. Jewels significantly impact a watch’s value and performance by improving accuracy and symbolizing luxury. Deciphering the jewel count in watch specifications reveals insights into craftsmanship and longevity. Proper maintenance, including regular servicing and DIY care, ensures optimal performance of jeweled watches. By appreciating the significance of jewels in timepieces, one can truly grasp the intricate blend of artistry and engineering that defines these exquisite accessories.

Frequently Asked Questions

Why do cheaper watches have fewer jewels?

Cheaper watches often have fewer jewels because they are usually equipped with quartz movements. Quartz movements rely on electronic mechanisms rather than mechanical components, reducing the need for jewel bearings. Additionally, the cost of incorporating jewels into the movement adds to the overall production cost.

Can adding more jewels improve a watch’s accuracy?

While adding more jewels can reduce friction and improve the overall performance of a watch, it does not directly guarantee better accuracy. The accuracy of a watch is influenced by various factors, including the movement design, regulation, and adjustment, in addition to the jewel count.

https://en.wikipedia.org/wiki/Jewel_bearing

https://www.govbergwatches.com

https://www.hydeparkjewelers.com

https://www.britannica.com/technology/escape-wheel

https://www.nps.gov/articles/mohs-hardness-scale.htm

https://www.prestigetime.com/blog/what-are-the-jewels-in-a-watch-for.html

Leave a Reply